http://www.sulzermetco.cn/

Sulzer Metco coats and enhances surfaces, produces materials and equipment for these purposes and develops machining processes for special components. Our state of the art products, solutions and services are delivered through a global sales, customer support and manufacturing network.

Our Products & Services

Advanced surface technology equipment, systems and materials

Thermal Spray and thin film coatings and surface enhancement services

Manufactured turbine, automotive and other components

Global customer support services

Our Market Focus

Sulzer Metco focuses on industrial and technical markets such as:

Aviation

Power Generation

Automotive

Industrial/specialized markets

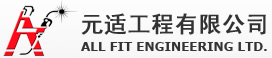

Plasma spray:

|

|

Plasma Spray is perhaps the most flexible of all of the thermal spray processes as it can develop sufficient energy to melt any material. Since it uses powder as the coating feedstock, the number of coating materials that can be used in the plasma spray process is almost unlimited. |

|

Features of the Atmospheric Plasma Spray Process:

Large choice of coating materials, including metals, alloys, ceramics, cermets, carbides and others.

Coating systems are possible, using layers of different materials.

Produces surfaces for a wide variety of applications, including resistance to many different types or wear and corrosion mechanisms, desirable thermal or electrical characteristics, and surface restoration and dimensional control.

Excellent control of coating thickness and surface characteristics, such as porosity and hardness .

No heat affected zone or component distortion.

High deposition rate.

High bond of the coating to the substrate.

Coating of complex geometries.

Easy masking of areas that should not be coated.

Process can be fully automated.

Coating of internal geometries possible.

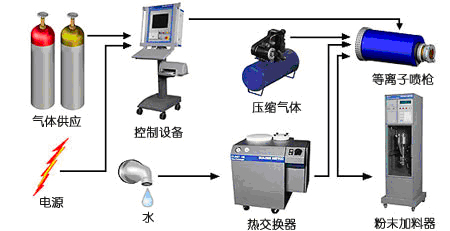

The HVOF (High Velocity Oxy-Fuel) process efficiently uses high kinetic energy and controlled thermal output to produce dense, low porosity coatings that exhibit high bond strengths, some of which exceed 83 MPa (12,000 PSI), low oxides and extremely fine as-sprayed finishes.

|

Features of the HVOF Spray Process:

Produces very clean, hard and dense coatings with fine, homogeneous structures

Coatings are tenaciously bonded to the substrate

Low to compressive coating stress allows very thick coatings

Excellent for wear and corrosion resistance

Recommended for carbide coatings and often recommended for superalloy coatings

Very thick coatings are possible

Surface finishes are generally smooth and can be used in the as-sprayed condition

Coatings can be ground and/or superfinshed

Coating of complex geometries

Easy masking of areas that should not be coated

Process can be fully automated