The EGW(Electro Gas Welding) is a high deposition welding process that uses retaining shoes to confine a molten metel for vertical progression welding.

Egw is considered as a highly automatic process as it requires closed loop current sensing or other means, to govern travel speed & to maintain electrode stick-out automatically without operator interference.

ALL TIME Electro Gas Welders Features:

●Adopts EGW (Electro Gas Welding) process for high speed carbon steel vertical welding with FCAW (Flux Cored Arc Welding) Process option for alloy steel vertical welding

●Lightweight travel carriage, self-propelled, weatherproof, fully contained operators cabin which allows safe access to the weld joint and easy set up and install

●Lightweight Aluminum track, quick mount electro magnets , easy assembly and disassembly;

●Real time monitoring of arc and automatic control of weld pool level, welding gun position and automatic adjustment of electrical stick out;

●Sequence control in “Auto mode” to allow one button startup.

●Onboard- self-contained continuous water cooling system Fully integrated with LINCOLN electric welding systems as standard (other welding systems on client’s request) SEW drive system for reliable and steady travel

●Different standard configurations for site erected Bottom Up and Top Down erected storage tanks or heavy wall cylindrical structures (eg. towers, blast furnace).

All Time offers 3 versions of vertical welders for various needs:

| EGW V: | Single Pass Electro Gas Vertical Welder for bottom up constructured tanks |

| EGW V/D | Single Pass Electro Gas Vertical Welder for top down constructured tanks |

| EGW BUG | Muliti Passes Vertical Welder for applications where single pass electro gas welding is not applicable |

Advantage for EGW V and EGW V/D:

High Deposition Rate- approximately 20 × faster than manual welding when electro gas welding is being adopted. An operator can weld over 2.5m long vertical seams less than 1 hour.

Weld can be done in single pass with no inter-pass cleaning.

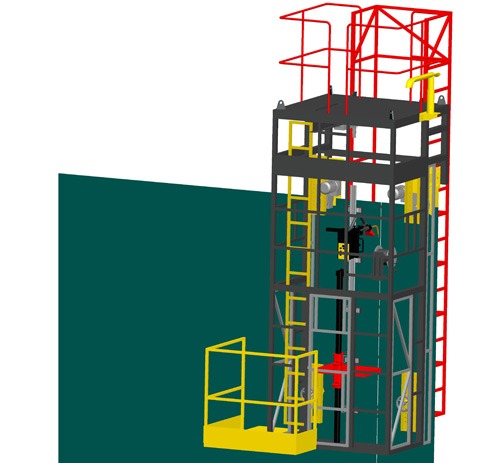

Self-Propelling Wind Shielding Frame:

Rides on top of the tank shell and travel laterally along the tank diameters. Provides the "indoor" condition that is critical for high quality site welding.

Travel Carriage & Linear Oscillator (required for over 25mm plate):

Travel Carriage raises the special welding torch vertically upward and the Linear Oscillator manipulates the welding arc in and out of the joint.

In case of single pass electro gas welding, a close loop sensing control is attached to the travel carriage to maintain travel speed of the carriage automatically.

Elevated Operation Platform:

The Powered Operation Platform(lift by a power winch) is designed for the comfort of the operator to travel with the welding carriage.

The operator can easilly control the travel direction of the platform by pressing the up/down button on the pendent.

Power Source:

Rugged Lincoln USA CC/CV power supply with excellent welding performance is a standard component for every All Time girth welder.

Wire Feeder:

Lincoln USA wire feeder is normally supplied with All Time electro gas welder. It is mounted on the power elevated stand for operator easy access.

General Technical Data:

●Auto Travel speed: 0~250mm/min

●Rapid-Travel speed: 550mm/min

●Oscillation stroke: 50mm

●Dwell time: 0~3sec

●Carriage weight: 15kg

●Frame weight: 2000kg

Field Application:

●Tradition top down constructed tanks

●Top down constructed(Jack Up) tanks

●Stainless steel tower

●Heavy wall Steel mill blast furnaces

●Double shell cryogenic(LNG/LPG) tanks

●Ship panel